Hobbit Hole? Earthship? Here are 9 Eco-Friendly Home Types That Support Greener Living

One is literally built from raw earth.

Written by May Ortega on April 20, 2023

There are countless things you can do to make your living space more eco-friendly, but what would it be like to live in a home that is inherently better for the environment? In honor of Earth Day, we've crafted a list of nine home types that incorporate green home design principles intended to be low-impact on the planet, inside and out.

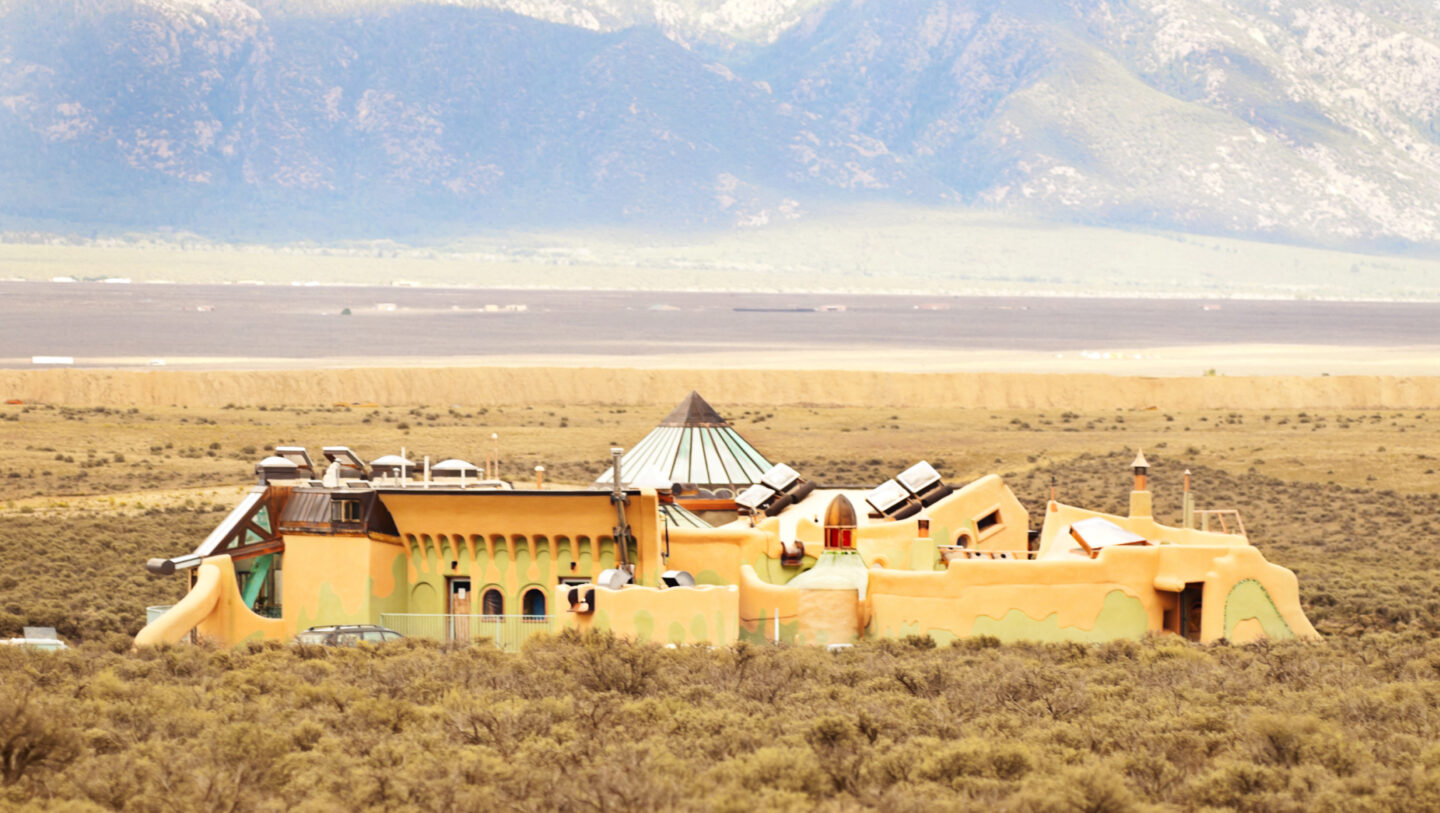

1. Earthship

While an “Earthship” home might sound like something straight out of a sci-fi movie, it’s actually a real home type that’s become increasingly popular in recent years. A spokesperson with Earthship Biotecture, the official Earthship education organization, said this type of home is now in 45 states and 40 countries. Taos, New Mexico, is home to a large Earthship community holding 95 such homes. Check out this colorful Earthship in Taos, or the house known as “The Euro,” once used as the showcase model for a particular Earthship design style.

“Earthship” — a term coined by self-proclaimed ‘biotect’ Mike Reynolds — refers to homes that are responsibly constructed out of earthen materials, generate their own electricity, naturally cool down and heat up with the seasons, and collect their own water.

Earthship designers focus on six specific principles that guide the creation of these homes, according to Andy Bratz, designer and president of Biotecture Planet Earth, a nonprofit that promotes Earthships: building with recycled and natural materials, water harvesting, food production, thermal solar heating and cooling, solar and wind energy and contained sewage treatment. Let's explore some of these principles a little further:

Recycled materials

Earthships are built using common recyclables such as bottles, cans and tires. “There is a lot that goes into building an Earthship,” Bratz said. Bratz has 1,200 tires in his Earthship home — enough to be recycled from 300 cars — and each tire is individually filled with cardboard and dirt. Another layer of labor comes into the equation if bottles are used. At Bratz’s home, he has two walls that are made out of a combined 1,700 bottles that were all individually cut, cleaned and categorized for a specific design.

Water harvesting

Not only do Earthships produce their own water and energy but they also treat the sewer onsite. Earthships recycle water four times, “which is more than any other structure I have seen in the 30 years I have been designing homes,” Bratz said. At Bratz’s home, the metal roof collects rainfall which is stored in cisterns that can hold up to 6,800 gallons of water, which is used in four ways:

- The rainwater filtered for household tasks like showers, dishes and laundry.

- Used greywater is filtered through peat moss, gravel and soil, to water the plants.

- The greywater is pumped into a storage tank which is then used for flushing the toilets.

- The blackwater from the toilets is processed through a septic tank, providing clean water for the exterior yard and plants.

Bratz says he was drawn to Earthships because of the idea of “being off the grid 100%,” which includes not having to rely on anyone or any company for utilities or services. With an Earthship home, he says, he feels he’s able to be “independent from the system at an affordable price.”

2. 3D-printed house

A 3D-printed home is just that: a home that was created using a giant 3D printer. But it’s not made of plastic; this relatively young tech often uses a concrete mixture that’s distributed layer by layer to eventually make up the whole home. While 3D-printing home construction has been around for nearly a decade, it’s just starting to break ground when it comes to housing in the U.S. 3D-printed home projects have popped up in places like Texas, Colorado and Michigan.

While 3D homes are typically not zero-waste, the supply chain, resources and logistics involved with building a 3D-printed house are generally considered more streamlined. The printer itself is controlled by a computer that gives the machine specific instructions for the dimensions and shapes of each section of the house. This kind of specificity and precision can be more difficult to accomplish with traditional building techniques, and oftentimes, that’s how waste is created.

A variety of materials can be used to 3D print homes, depending on the printer that’s being used and the desired design of the house, but materials such as patented concrete mixes, clay, and cement are often used. Some companies are exploring more innovative materials and techniques to maximize the eco-friendliness of a 3D-printed home.

3. Passive house

Passive homes are designed to reduce energy consumption and minimize the house’s environmental impact. In order for a home to achieve certification as a passive house, it must meet strict energy efficiency standards that are set by PHI (the Passive House Institute) or Phius (Passive House Institute US), which includes limits on energy consumption for heating and cooling and requirements for insulation and airtightness.

Often described as “airtight,” passive houses are constructed in a way that makes them highly insulated, increasing the home’s self-sufficiency for heating and cooling. Due to the public’s awareness of — and drive to take action against — climate change, this house design is becoming increasingly popular in places with colder climates, like Upstate New York. The International Passive House Association says more than 41,000 homes around the world are Passive House certified, including homes that have been retrofitted to meet their strict standards. The association says those homes total nearly 4 million square meters. Ten years ago, that number was around 1 million.

Design features and technologies used in passive houses might include high-performance windows, ventilation systems that recover heat from exhaust air and efficient cooling and heating systems, such as passive solar heating — which involves positioning the building and its windows to maximize sunlight that enters the building. Green roofs — roofs that are partially or completely covered with vegetation and can help cool the home — are also often common features of passive houses. Though incorporating these features means that constructing a passive home can be more costly. These costs can vary, but Phius claims building to their standard costs 3% to 5% more than a traditional home of a similar size.

4. Tiny home

Tiny homes are compact houses that are generally 400 square feet or smaller. While not all tiny homes are built to the same green standards, their small footprint alone tends to bring obvious sustainability benefits. Owners of tiny homes typically live with less, and the house itself generally requires reduced energy usage and can offer a more affordable path to a greener lifestyle.

Maria Saxton, a Virginia-based community planner, surveyed 80 tiny home downsizers across the United States and found that overall, ecological footprints were reduced by about 45 percent on average compared to their footprints before they downsized.

One aspect of this, of course, is that tiny homes require significantly fewer materials than their single-family counterparts to build, Dan Louche, builder and owner of Tiny Home Builders, says. In comparison, the average square footage of an occupied home today is 1,753 square feet, according to Zillow research.

“This means less wood harvested from forests, less products produced in a factory, and less transportation of goods to the store and ultimately, the consumer,” he said.

Since tiny homes are so popular, there are endless numbers of guides online on how to make one more sustainable — whether that means using recycled material as insulation, adding home solar, or installing energy-efficient features and appliances. And less square footage means investments like ENERGY STAR-certified windows tend to be less costly, while also providing the benefit of savings on your energy bill.

5. Earth-sheltered

There are two types of earth-sheltered homes. If you’ve ever watched “Lord of the Rings”, you’ve seen a bermed earth-sheltered house, or a green-roofed home. The Baggins home in LOTR, located mostly underground with its front door exposed, is one such structure. Here’s a different take on a bermed home in Montana that, according to the listing, runs on solar energy.

Then there are underground earth-sheltered homes; these are built completely underground, or “below grade.” These types of homes often include a courtyard or atrium to give the home a more open feel and access to sunlight. And solar heat — the heat that comes into a home through sun-facing windows — is minimal because there is so little exposed, so there’s little need for central cooling.

Earth-sheltered homes can be very energy efficient if located in dry areas with very hot or very cold climates, according to the U.S. Department of Energy. The ground surrounding the home can insulate it in bitter winters and absorb heat from its walls in scorching summers. One Colorado-based earth-sheltered home building company says these structures are often up to 90 percent more energy efficient than a traditionally built home.

Though very unique, these structures can also be highly complex to build, since you have to consider things like the direction of the area’s natural drainage, the topography, and whether the soil in the area is conducive to supporting the weight of a home; they are often built out of concrete, after all.

6. Cob

No, cob houses are not made of corn. They’re constructed from a combination of clay, sand and straw. The material — which is referred to as cob — is mixed with water and then expertly sculpted by hand. These homes are similar to adobe houses, but unlike adobe, which is formed into bricks and hardened before building, cob structures are sculpted while the mixture is still wet. This technique means the final product’s exterior walls aren’t completely uniform; oftentimes, they have dips here, curves there, and completely straight edges or corners aren’t very common. In fact, many cob homes are round. This cob house in California incorporated lots of wood into its design for structural support and some design flare.

Many cob builders are drawn to the practice for its connection to the natural environment. The materials that make up cob houses are able to absorb and retain heat from the sun, which provides natural heating and cooling systems. There is also a lot of freedom for the builder, Kentucky-based cob house builder Ziggy Liloia explains.

“There’s no limit to building with cob. Houses can take on any shape, design or style, and the walls are load-bearing, so the need for framing is reduced or eliminated.” (This process replaces the need for traditional construction techniques which can be more disruptive to the surrounding environment, according to Liloia.) “It's up to the designer and homeowner to decide how to best utilize cob as well as consider other ways to improve energy efficiency, responsible resource usage, and building according to individual and family needs.

Known for being durable and stable, in many ways, cob houses don’t feel like conventional homes. “There’s a profound feeling of shelter, protection and sturdiness,” Liloia says. “Being wrapped in something handmade is a wonderful experience.”

7. Prefab

Simply put, prefab is an umbrella term that is short for prefabrication, the practice of building home parts in a manufacturing facility before transporting them to a final location for assembly. The word “prefab” might refer to modular or manufactured homes, mobile homes, container homes, kit homes — which include pre-cut pieces and are assembled like a puzzle on-site — and accessory dwelling units (ADUs). The National Association of Home Builders Modular Home Building Council assures prefab homes are held to the same quality standards and building codes as site-built homes.

Prefab homes are built with the major components, like the roof, floors and walls, constructed in a climate-controlled factory off-site. This saves on materials, time and labor costs, and ultimately helps prefab builders cut down on greenhouse gas emissions. “Materials are cut exactly to size with little or no waste, and labor works in a highly efficient assembly line, completing an entire home within eight to 12 days in the factory and another four to six weeks on location,” says Or Michaelo, the founder of The Home Gallery, which offers factory-built homes designed by architects for home buyers in California. Michaelo says his clients can expect to skip about six to seven months of construction and labor days per home.

Manufacturers of prefab homes offer a wide range of material choices that can range from traditional to eco-friendly. They also come in a variety of styles, from grand colonials to cozy bungalows. The prefab building process gives home buyers the ability to customize the design to fit their needs and preferences, meaning they can choose a builder that implements more eco-friendly practices — like using more sustainable materials like recycled wood and steel, for example, or incorporating solar energy.

8. Zero carbon

When anything is dubbed “zero carbon,” that usually means it has a way to offset its carbon footprint via renewable energy. Zero-carbon homes are no different. Electricity and solar energy often replace natural gas and other such utilities.

The Department of Energy says homes need to meet various federal regulations to be certified zero carbon, down to their construction. That includes having all Energy Star appliances, using solar water heating systems, and triple-glazed windows. And when a home is being built with zero carbon in mind, even the location of its doors and windows may be dependent on where exactly the property is, and the direction of the sun throughout the day. Even then, zero-carbon homes look like any other home; it’s the inside that counts.

9. Geodesic dome

The keyword here is “dome.” This type of home is a huge dome made up of many triangular or circular panels. Check out what the inside of one looks like in this listing’s 3D tour. Geodesic domes have a very futuristic look, especially for a home style that was first created in the 1950’s in the U.S. There are geodesic domes of all sizes and materials all over the world. You’ve probably seen a couple in your life, large enough for a small group to sit in. They’re very popular in areas offering Aurora Borealis tourism.

People who choose to call a dome home for sustainability reasons will opt for something other than wood. But the biggest reason geodesic domes are considered environmentally friendly is because of their low carbon footprint. Because they have less surface area and are aerodynamic, they are easier to heat up, cool off faster, and, depending on how many windows you install, they’re easier to brighten up naturally. They’re also more accessible than other types of homes (depending on your preferred housing goals) because there are companies that sell DIY geodesic dome kits as large as 630 square feet.

How much home can you afford?

At Zillow Home Loans, we can pre-qualify you in as little as 5 minutes, with no impact to your credit score.

Zillow Home Loans, NMLS # 10287. Equal Housing Lender

Get pre-qualifiedA great agent makes all the difference

A local agent has the inside scoop on your market and can guide you through the buying process from start to finish.

Learn more